Inside EVSE

Inside EVSE

Electric Vehicle Supply Equipment (EVSE) provides a connection between EVs and the power they need to charge their batteries. Although the EVSE is commonly called a charging station, this term is not technically accurate because the actual charging components are inside the vehicle.

Established by the Society of Automotive Engineers (SAE), the most common types of charging stations being installed today are the:

- SAE Level 2 (equivalent to International Electrotechnical Commission [IEC] Mode 3): A level with a 240V single-phase, 19.2kW, and up to 80A (typically 32A) for residential and commercial use.

- SAE Level 3 (equivalent to IEC Mode 4): A level also called Direct Current Fast Charge (DCFC) with 200–600VDC, up to 240kW, and 400A for commercial use.

In North America, an EV typically comes with a Level 1 portable charging station designed to plug into a standard 120V power supply or with a Level 2 portable unit. However, there are many other configurations of residential and commercial charging stations, in both AC and DC, that deliver a range of power outputs, load capabilities, and different connector types. Some are regionally standard (North America, Europe, and China), and some are vendor specific (Tesla uses a proprietary connector). Regardless of these differences, all EVSE units have components that enable them to perform the same basic functions.

Charging stations are typically housed in a National Electrical Manufacturers Association (NEMA) rated enclosure that can be a box on the charging cable, a wall-mounted unit, or a tower. AC power goes into the enclosure, either through a plug (mostly for portable units) or a hardwired connection, and a cable comes out of the enclosure with a connector that connects to the vehicle’s charging port. In the case of DCFC, the EVSE enclosure also contains components that rectify the AC power to DC.

In its simplest form, a charging station contains a main relay for switching power to the vehicle on or off, a control module that controls the main relay, and a power supply, typically 12VDC, that powers the control module and relay. When an EVSE cable is plugged into an EV, the connector has terminals for high voltage power used for charging and pilot connectors for a low voltage connection to the EVSE’s control module. As soon as the connection is made, the control module looks at power levels on the pilot connectors. Those power levels indicate that the cable is properly connected, that there are no ground faults in the connection, that the systems in the car are ready to receive a charge, and that the charging station is ready to deliver power. Only when all those conditions are met will the control module activate the main relay which powers up the cable connected to the car. This connection and readiness verification typically take a couple of seconds. Many connectors have a mechanical or electronic latch. If the latch is disengaged, a proximity detector triggers the control module to immediately shut off the main relay, cutting power to the EV. This prevents arcing at the terminals when plugging or unplugging the cable at the EV’s charging port.

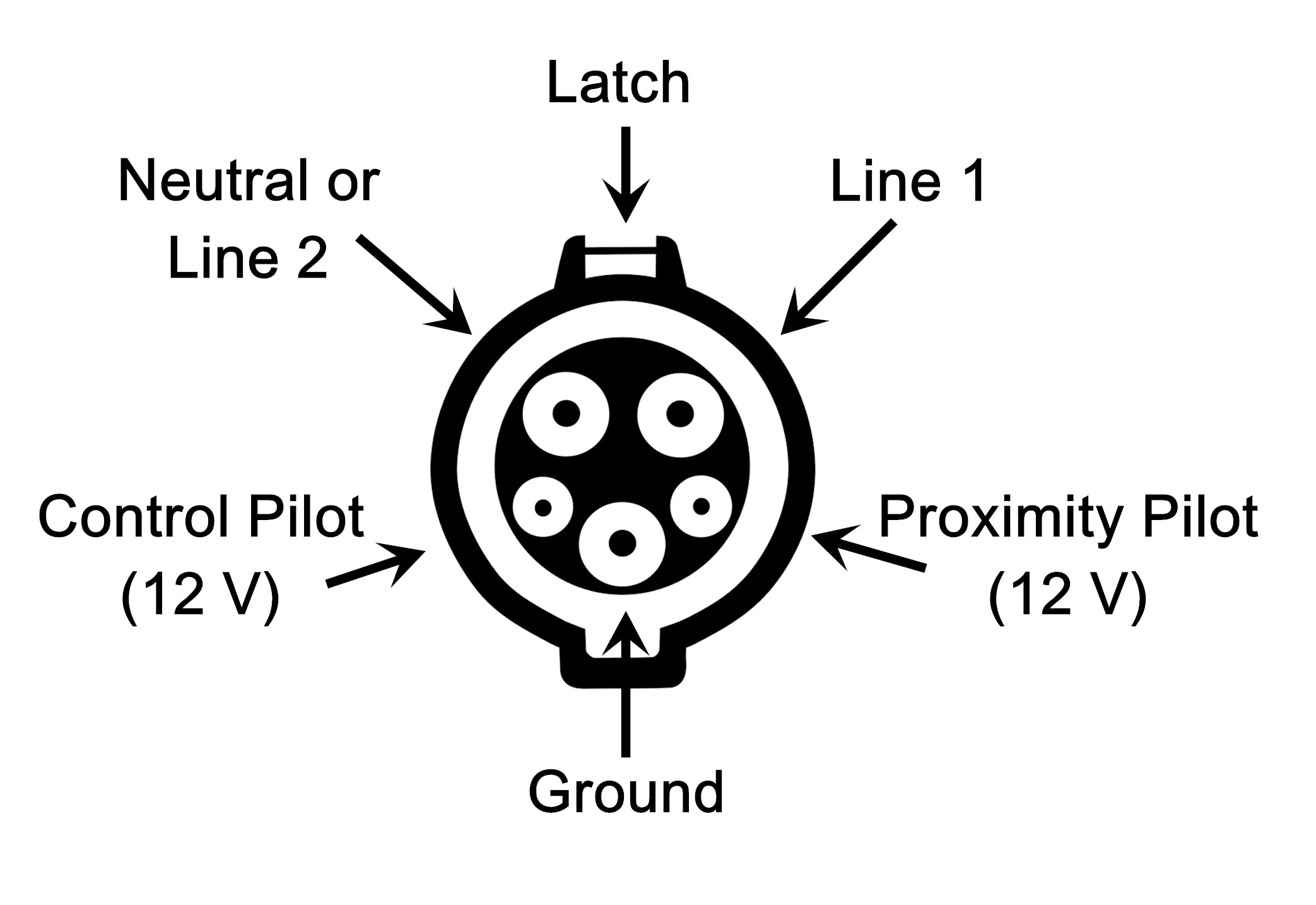

Although there are many different EVSE connector configurations, all the connectors have pins that enable these basic functions. Figure 1 shows the pin configuration for a J1772, which is the standard connector used in North America for Level 1 and 2 charging stations.

Figure 1: All EVSE connector configurations enable the basic functions. The J1772 EVSE connector is the standard for North American Level 1 and 2 charging.

More sophisticated charging stations contain microcontrollers that can be programmed to perform certain functions such as adjusting power output, monitoring charging progress, connecting to the Internet, and interacting with mobile apps that enable users to remotely control the charging station.

Residential EVSE Configurations

At the present time, residential charging stations far outnumber public charging locations in North America, and this is likely to prevail in coming years. Level 1 and 2 AC charging stations are the most common for residential applications, although Level 1s are being displaced by faster charging Level 2s. Configuration options typically include:

- Power output: Level 1 (single phase 120VAC, typically operates at 10A and 1kW) and Level 2 (240VAC typically operates at 32A and greater than 7kW, although there are lower power versions in the 16–20A range). More power means faster charging, and the trend is toward higher output units.

- Hardwired versus plug-in: The biggest difference between the hardwired and the plug-in EVSE is that plug-in units are portable. Although hardwiring creates a cleaner installation, plug-in installations cost less, and the units are portable, which makes them easier to move or replace (and easier to steal). Level 2 units typically connect to a 40 or 50A 240V service, depending on their power output. A maximum output Level 2 unit (19.2kW, 80A) would require a 100A circuit.

- Cables and connectors: Charging cables should be as long as possible. The National Electrical Code® (NEC) limits cable lengths to 25ft. For connectors, the North American standard for Level 1 and Level 2 AC charging is J1772. Tesla uses a proprietary connector, but adapters are available.

Public and Commercial EVSE Configurations

Public charging stations come in a wide range of formats and power output offerings. These include everything from single-port wall-mounted units to multi-port towers. The most common output configurations are AC (Level 2) and DCFC (Level 3). Many commercial charging stations allow users to select AC or DC charging options.

Commercial charging stations perform the same basic connection and charging functions as residential units, but higher capacity units have more sophisticated controls for load balancing, communicating with the power grid, metering for user billing, and networking connections. There are also a greater variety of connector options. Table 1 lists the most common connector types in use around the world today:

Table 1: Common EVSE connector types differ according to region.

Connector | Region | Output | |

J1772 (Type 1) |  | North America, Japan | AC |

Type 2 |  | Europe, China | AC |

CHAdeMO |  | North America, Europe, Japan, China | DC |

J1772 Combo (Type 1 CCS ) |  | North America, Europe | AC and DC |

Type 2 Combo (Type 2 CCS) |  | Europe, China | AC and DC |

Tesla |  | North America, Europe | AC and DC |

EVSE design is rapidly changing. There is demand for higher power and faster charging capabilities, which means an increasing deployment of DCFC stations and higher power Level 2 units. As configurations evolve, there remains considerable competition between connector and charging types. Efforts are under way to settle on connector standards. For example, there are indications that the Type 1 Combined Charging System (CCS) may be evolving into a standard in North America and Europe.

The current diversity of connector types is partly the result of car manufacturers using different port connections on their EVs. From the EVSE charging station perspective, at any point in time there are many vehicles on the road with different connector types. Some EVSE manufacturers provide connector options and build charging stations with multiple charging cables equipped with different connector types. Many EV owners carry adapters with them so they can charge at almost any public charging station. Tesla uses a proprietary connector that only connects to Tesla cars, and at the present time, Tesla DCFC stations outnumber all others in North America and Europe.

Cost Trade-offs

Cost is an important factor in EVSE deployments. Generally speaking, the higher the power output, the greater the cost of the unit, and the greater the installation costs. Installation costs for Level 1 and Level 2 units are typically as much or a bit more than the cost of the charging station itself. Although Level 1 chargers cost less to purchase and install (using 120VAC power), they are not practical for today’s larger battery vehicles, unless the vehicle is rarely used.

DC fast charging EVSE options typically costs 10 to 20 times more than Level 2 chargers, and they can cost a lot more than that for little more than the cost of the charging station itself. Although Level 1 chargers cost less to purchase commercial installations. This additional cost is due to the fact that a DC fast charging EVSE has more costly components including rectifiers and controls, and they require 480VAC power input.

Continuing Evolution of EVSE

As more EVs hit the road, both private and public EVSE deployments are accelerating. For residential deployments, the goal is to have a charging station that can fully charge the EV overnight. The most common configurations are 7.7kW with 32A and 9.6kW with 40A for Level 2 units.

In the public domain, DCFC stations are all the rage. Larger batteries and the demand for faster charging is resulting in much higher power charging stations. Christopher Michelbacher notes that, “You're starting to see a trend to higher powered charging as manufacturers strive to meet that customer need for fueling parity with their internal combustion engine vehicles. For instance, every DC fast charging station deployed by Electrify America is 150kW capable with the ability to upgrade to 350kW. They were actually the first company in the US to get a liquid cooled cable certified by Underwriters Laboratory.” It could go further than that. Some manufacturers are developing liquid-cooled charging cables that enable charging up to 500A at 1000VDC. This could provide 100km of range in three minutes of charging.

Comments

Post a Comment